History and Present

KLOCOK Poprad, sro is a family company that emerged from KLOCOK a spol., vos, founded in 1993. The company was officially founded as KLOCOK Poprad, sro in 1995 and has since become a leading manufacturer of architectural concrete elements in Slovakia.

The company works with architects and designers to create high-quality architectural concrete elements with a variety of textures and finishes. It also offers UHPC concrete, a durable material that does not require a metal structure.

The company has a history of innovation and continues to develop new products in line with their values.

Specializing in custom production of architectural prefabricated concrete elements requires small-batch or piece-by-piece manufacturing, resulting in unique concrete elements.

Products KLOCOK

- Concrete furniture for the street and garden

- Concrete slabs for outdoor and indoor use

- Large-format paving slabs of any shape for outdoor areas and gardens

- Concrete exterior and interior stairs

- Exterior walls and 3D elements with an inscription, logo or other corporate identity symbol

- Wall cladding boards and window sills

- Facade elements

- Elements of cemetery architecture

- Other custom architectural elements

Vision

Slovakia is a small country with a market that provides little opportunity for large-scale production of architectural concrete elements for beautifying the exterior of urban areas, streets and gardens according to designs by renowned designers or architects.

We have therefore focused on developing sophisticated, custom, small-batch, factory-based production, where we do not (yet) offer catalog collections of products. We will continue to improve our ability to produce (almost) any 3D architectural element not only quickly, but also at an acceptable price.

After more than 30 years of specialization, we want to maintain and strengthen our position as a significant Slovak manufacturer of prefabricated architectural concrete products and be a competent partner for an increasingly large circle of designers, architects, investors and construction companies not only in Slovakia but also abroad.

Quality

KLOCOK Poprad sro has more than 30 years of experience in the production of prefabricated architectural concrete.

We apply an in-house quality control system and the product properties are in accordance with the data specified in the relevant technical certificates and technical standards.

In the production of concrete products, we use input materials and substances that comply with the relevant technical standards.

Material and Technology

Concrete is a mixture of mineral components (cement, sand, gravel, coloring pigments), water and improving additives. A plastic to liquid mixture is formed and after it hardens a product with the required physical properties. All components used are in accordance with the requirements of the standard STN EN 206-1: 2002 Concrete. Part 1: Specification, properties, production and conformity.

In our factory production of concrete elements, we use exclusively the wet production method (Wet Cast Method).

The resulting properties of our products comply with the requirements of the following standards:

- STN EN 13198: 2004 Precast concrete products. Street and garden furniture.

- STN EN 13369: 2005 General rules for precast concrete products.

| Volumetric weight | from 2300 to 2450 kg/m³ |

| Cubic compressive strength after 28 days | from 30 to 75 N/mm² |

| Bending tensile strength | from 3 to 8 N/mm² |

| Absorbency | from 4 to 6% |

| Weather resistant | yes |

Architectural Concrete

We use this term for a wide range of concrete elements of various shapes and sizes that have an important decorative function. Their shape, color, surface structure and exceptional quality contribute significantly to the appearance of a construction work, part of a building, or the concrete product itself. The essential thing here is the unlimited choice of shape, color and surface structure. The complex shape of a new product is a challenge for us. If it is necessary to optimize its shape from a technological point of view, we do this in cooperation with an architect or designer.

We would be happy to support you in implementing your unique ideas in the creation of concrete elements. Our experts have extensive knowledge of this material and will be happy to answer your questions.

Know- How

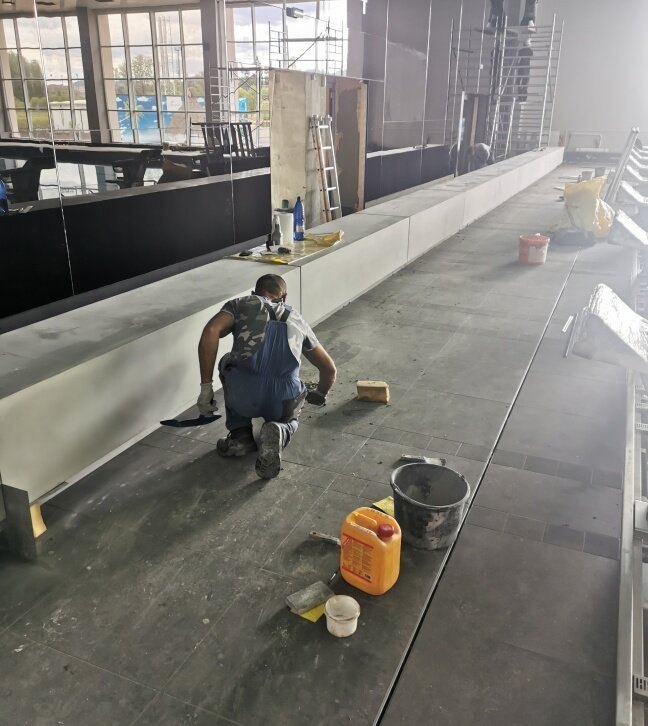

KLOCOK Poprad sro designs, models and manufactures high-quality architectural concrete elements. To achieve this result, we work in close cooperation with architects, designers, engineering offices, who provide us with files and plans that we can quickly convert into molds and then into our precast products through production processes.

We will answer all your questions and, if necessary, guide you to avoid potential problems or to avoid paying for something you don't actually need.

We adhere to the rule that nothing is impossible and behind each of our works is more than 30 years of experience in concrete casting and manufacturing molds for concrete prefabrication.

The Forming Process

Concrete is a mixture of aggregates, cement, water, color pigments and finishing additives. Everything is mixed according to various recipes. Then the concrete is poured into molds and compacted mechanically or the concrete mixture is compacted itself.

After the CP is accepted, the mold is manufactured, which is mostly done by us. The molds can be made of wood, steel, fiber-reinforced resin, depending on the number of castings or the complexity of the precast. We can also obtain 3D textures by inserting matrices into the mold.

Surface Treatments

After removing the precast concrete from the mold, it then enters the finishing phase. The customer can choose from various options: exposed concrete, micro-etched concrete, polished concrete, stamped concrete. You can see the individual surface finishes live if you visit our store in Hranovnica.

You can find our current surface treatments in the documents section.

It is interesting to note that depending on the chosen finish, starting from the same identical block, we can obtain radically different color variations and textural effects. Architectural concrete requires real expertise and we are here to help you.

Nature of products and their price

From the point of view of Act 133/2013 Coll. on Construction Products, these are products that can be placed on the market without meeting the conditions of this Act, as defined in §2 (2). This is because they are precast concrete products from custom production, manufactured individually or modified in a non-series manner according to the individual requirements of the customer, based on a specific order and supplied technical documentation, and the contractor responsible for the safe incorporation of the product into the structure installs the product into the specified specific structure.

You will not find a price list on our website. Each project is unique, with many factors that affect its price. Quantity, shape, size, color shades, surface structures, anchoring elements and project schedule all affect the price. If you require a quote for your project, please provide us with as much relevant information as possible. We approach each order individually and prepare a quote for the production and delivery of these products after jointly optimizing the design of the elements, according to the architect or investor's ideas, taking into account our specific material and technological capabilities.

Packaging and Protection

During meticulous and demanding production, we also place emphasis on careful packaging of your concrete products in order to avoid any problems during transportation or loading/unloading of the products.

It is important to communicate in advance when and in what vehicle you will pick up the products or how they will be transported to you. The principle applies to products made of exposed concrete: handle them as if they were made of glass.

The packaged precast elements are protected against shocks during transport with wood, polystyrene, cardboard and are covered with a transparent plastic film. They must also be handled with the utmost care and respect on the construction site. Concrete is not light, you need forklifts or cranes to lift these elements. Preferably use wide textile straps.

After Sales

Concrete is repairable in case of light impact, but there is always a risk that the repair will be easily visible. If you need any intervention (adjustment, repair), ask one of our specialists.

Career

KLOCOK Poprad, sro has long specialized in custom production of architectural prefabricated concrete elements. It is a demanding small-batch or piece, factory production of concrete elements for beautifying the outdoor environment. The company has many years of experience in this area and a good position on the domestic market. Our turnover is growing every year and the company is deepening its specialization in this area. Therefore, we are constantly looking for workers to whom we offer interesting employment in non-monotonous activities, where the result is a beautiful concrete product.

© 2024 Copyright | Privacy Policy